There are several physical methods that decrease scale formation rate. All of them promote hardness salts crystallization in water column and prevent crystals from reaching dimensions necessary for deposit formation. Ultrasonic technology stands apart of this group, since it acts on scale formation and precipitation in several different ways simultaneously.

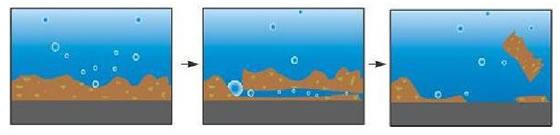

Firstly, when water is sound up by ultrasound of sufficient intensity, crystals of hardness salts formed in heated water are destroyed or split. When a solid comes in contact with liquid, scale is formed on it. This might be either heat exchange surface or particles suspended in water, which are crystallization seeds for salts dissolved in water. Under normal conditions, total surface area of particles suspended in water is smaller than the heat exchange surface area, and on this very surface scale is formed. But crystals of calcium carbonate present in the water, are split affected by ultrasound, and their average size reduces from 10 to 1 micron, and their quantity and the surface area increase.

SEE VIDEO: HOW ULTRASOUND FROM «ACOUSTIC-T» DEVICE ACTS ON SCALE!

When ultrasound acts in water, the quantity of crystallization seeds increases abruptly (by 1,000 times, approximately). This transfers the scale formation process from the heat exchange surface into water column, and leads to crystallization of salts directly in water mass, which is associated with occurrence of great amount of seed crystals under the effect of ultrasound, and to permanent formation, growth and splitting of salt crystals.

Secondly, ultrasound excites high-frequency vibrations in metal heat exchange surface. Spreading by the surface, ultrasonic vibrations prevent formation of scale deposits on it, slowing down precipitation of salt crystals formed. Due to different mechanical rigidity of metal and scale deposit layer, flexural vibrations of the heat exchange surface destroy the scale layer formed. But, if a scale layer has already been formed on the heat exchange surface, ultrasound destroys it. This process is accompanied by exfoliation and chipping of scale pieces. Dimensions of these pieces depend on the scale layer thickness, increasing with it. If previously formed scale layer is rather thick, there is danger of clogging and blocking of channels. Therefore, one of basic requirements for successful ultrasonic technology application is preliminary cleaning off, as far as practicable, the old layer of scale deposits.

THE METHOD OF EXCITING ULTRASONIC VIBRATIONS IN HEAT EXCHANNGE EQUIPMENT.

How are ultrasonic vibrations excited in the metal heating surface and heated water? As far as is known, ultrasound attenuates rapidly in air, but propagates unconstrained in metal and water. Ultrasound is "pumped" into boilers and heat exchangers as follows. Ultrasonic transducers, ultrasonic transducers, are welded to the installation. There is a core from magnetostrictive material, a specific alloy capable of change its dimensions under the effect of electric current flowing in the core winding, located inside the transducer. In anti-scale devices «Acoustic-T», one of the best magnetostrictive materials - permendur, representing cobalt and iron alloy with vanadium additives - is used. The core from permendur is soldered to a steel tip prepared for welding and by which the transducer is welded to the equipment to be protected.

MAGNETOSTRICTIVE TRANSDUCERS – ULTRASONIC TRANSDUCERS

Transducers are connected to ultrasonic generator by cable, by which they continuously receive electric pulses of specific shape with the carrier ultrasonic frequency of 18 to 25kHz from the generator. This electric signal is converted by magnetostrictive core into mechanical vibrations of the same frequency. Since the transducer is welded to protected installation and is its integral part, ultrasonic vibrations are excited in the entire structure of a heat exchanger of a boiler thus propagating by the heat exchange surface and irradiated by it to water. In this manner, we excite continuous microvibrations with the amplitude of several microns in the metal and water. These microvibrations are harmless for welding and rolling, but are destructive for calcium carbonate and other solid deposits.All day and all year round, acoustic anti-scale devices «Acoustic-T» protect the heat exchange surface against scale, not only from calcium carbonate and gypsum, but also from solid deposits of any origin, except for rust. Clear heating surface means intense heat exchange. Intense heat exchange means reduction of specific fuel consumption in boilers and specific heat carrier flow rate in heat exchangers that, in turn, means savings of gas, water and electric power. What is this but pure energy saving?

Order «Acoustic-T» now and we'll help you in selecting a version of antiscale devices for your particular equipment.