The most important consequence of antiscale devices application is heat exchange intensification that leads to reduction of heat carrier flow rate. This, in turn, means reduction of heat and hydraulic losses and energy carrier and electric power savings. Moreover, adoption of «Acoustic-T» devices provides:

- The use of plate heat exchangers with hard water

- Application of heat exchangers with smaller heat exchange surface area

- Reduction of return supply water by 5°, on average.

About Efficiency Of «Acoustic-T» Antiscale Devices

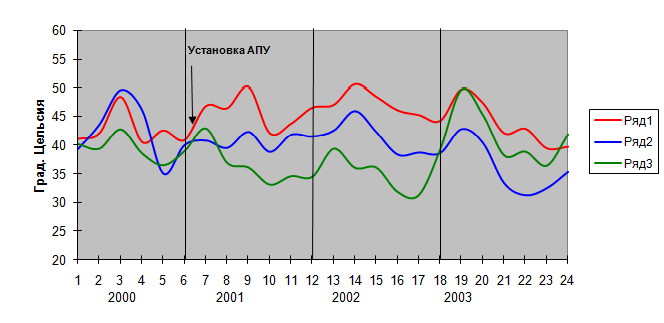

Extension of operating periods of the heat exchange equipment between its idle downtimes is indicative, but not the single advantage of application of acoustic antiscale devices. Our data maintain that the economic effect of abrupt reduction in the scale formation rate is established not only due to reduction of cleaning costs. Let us show that application of antiscale devices is also feasible during operation of a heat exchanger due to maintaining its rated parameters at the initial level. A pilot model of the effect of scale layer formed on performance of heat exchangers is as follows. The scale layer developing on the heat exchange surface hinders, due to its low heat conductivity, the heat transfer to heated water. To keep heated water temperature at the given level, heat carrier flow rate is increased that, in turn, rises average temperature of the heat exchange surface and stimulates faster scale formation. Increased specific heat carrier flow rate also leads to temperature increase at the heat exchanger output. But the heat quantity transferred to heated water remains unchanged. Heat quantity transported by the heat carrier through the heat exchanger is the only measure that increases.

Quantity that characterizes performance of a particular heat exchanger is the heat transfer rate. To determine value of the heat transfer rate instrumentation installed at heat stations is not enough, however, analysis of changes in some parameters monitored at heat stations gives an opportunity to make a qualitative assessment of heat exchanger performance.

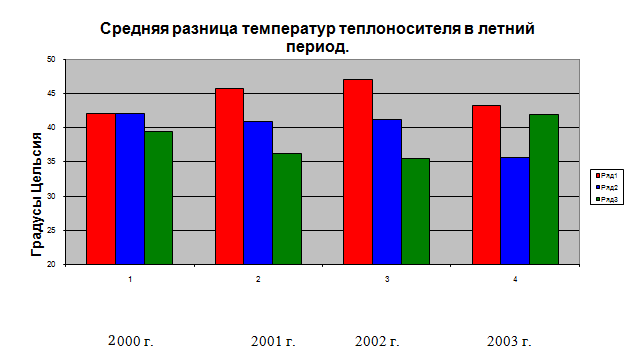

Comparison of overall performances of different heat exchangers is only correct subject to a set of conditions, among which equality of their attached loads, heat exchange surface areas, supply water temperatures at the heat supply station inlet and output temperatures of heated water are basic ones. Of course, such assessment of overall performance of heat exchangers in HWS system is only possible in summer time, when the heating system is off, because supply water flow rates and temperatures are recorded for the entire heat supply station.

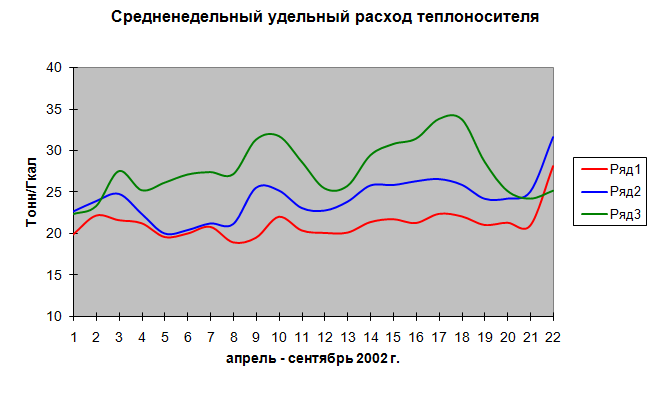

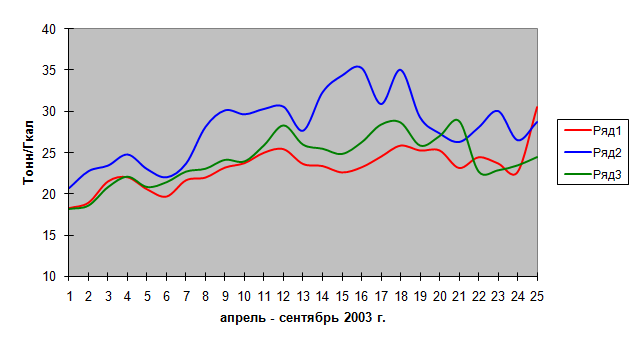

All these requirements were fulfilled by experts of Koltso-energo, LLC, when they equipped plate heat exchangers of HWS systems with acoustic antiscale devices in Moscow. At different times, heat supply stations were equipped with electromagnetic meters of heat quantity and "Acoustic-T" devices. Plots show specific flow rates of the heat carrier for three heat supply stations, one of which was equipped with acoustic antiscale device of "Acoustic-T" series (Heat Supply Station located at the address of Zorge Street, 6 – shown in red on the plots). The heating system was switched off and on in April and in October, respectively, and the heat quantity consumed in these systems is much higher than that in HWS systems. Contrary to HWS, heat loads of heating systems for these heat supply stations are different. Similar results were obtained by comparison for the rest heat supply stations. In all HWS heaters using "Acoustic-T" devices, specific heat carrier flow rate is by 10-30 % lower than in control units, not equipped with antiscale devices.

A significant dispersion of specific heat carrier flow rates in control HSS for heaters of the same type and heat exchange surface areas and connected loads indicates their different contamination degrees. Head difference of heated water is one more parameter for determination of heat exchanger contamination degree.

Thus is was shown experimentally that these heat supply stations not equipped with antiscale devices provided excessive consumption of heat carrier of 2.5 to 8 tons per every Gcal of heat produced in domestic hot water system. Heat and power losses are proportional to this excessive consumption.

At the moment, there are several types of ultrasonic antiscale devices at the market, much different in specifications and over performance. All the results shown only concern «Acoustic-T» acoustic antiscale devices produced by Koltso-energo, LLC.

Ultrasonic technology preventing scale formation is the Recommended Practice RD 153-34.1-37.410-00. [3], and when properly applied, it may pay off less than in a year after installation of antiscale devices.

Application of antiscale devices to plate heat exchangers

provides savings of electric power consumed by pumps for supplying increased heat carrier volumes in order to maintain heated water temperature at the output of contaminated heat exchangers at the given level. Reduction of costs for cleaning heat exchange surfaces completes the economic effect of acoustic antiscale device application to heat exchange equipment.

Experts from "Teploprogress-M" OJSC, Moscow, have determined overall performance of plate heat exchangers.

They have found out that heat transfer rates for units equipped with antiscale devices of «Acoustic-T» series produced by Koltso-energo, LLC are by 10 - 27 % higher than in heat exchangers, most close by specification and connected load of control heat exchangers.

Adoption of consumers to metering and paying for actually consumed heat quantity makes the heat transfer rate of heat exchange equipment the economic parameter, and active adoption of energy-saving technologies guarantees success for companies that generate and sale heat energy.

Order antiscale devices right now!